RV Push Lock

Secure and Convenient Cabinet Solutions

The RV Push Lock provides a simple push-to-lock, push-to-open function that prevents accidental cabinet openings on the road or water, combining safety with ease of use.

RV Push Lock Overview

The RV Push Lock is designed specifically for the demands of mobile environments. Unlike traditional cabinet locks, it uses a press-to-engage mechanism that keeps doors and drawers securely shut during travel. This prevents unwanted movement when vehicles encounter bumps, sharp turns, or rough waters.

Push-to-Lock, Push-to-Open Mechanism

A single press secures or releases the cabinet, reducing the risk of doors opening while in motion. Simple for end users and reliable in mobile environments.

Easy Installation & Replacement

Compatible with standard cutouts and furniture thicknesses, making it straightforward for OEM installations or aftermarket replacements.

Vibration-Resistant Design

Built to withstand bumps, vibrations, and uneven roads, ensuring cabinets remain securely closed throughout travel.

Multiple Finishes & Materials

Available in ABS, zinc alloy, or stainless steel, with surface finishes to match various RV and marine interiors, offering both durability and design flexibility.

RV Push Lock Specifications

Technical Specifications & Options

The RV Push Lock is designed for secure cabinet and drawer applications in RVs, caravans, and boats, offering vibration resistance, easy installation, and multiple finish options.

| Parameter | Details |

|---|---|

| Material Options | ABS Plastic, Zinc Alloy, Stainless Steel |

| Finishes Available | Chrome, Nickel Plated, Black Matte, Customized Color Options |

| Locking Mechanism | Push-to-lock, push-to-open system |

| Panel Thickness | Compatible with 15mm – 25mm furniture boards |

| Installation | Standard cut-out compatible, screw-in or snap-fit mounting |

| Durability | Tested for 20,000+ open/close cycles |

| Vibration Resistance | Secure under road and marine vibration conditions |

| Applications | RV cabinets, drawers, wardrobe doors, caravan furniture, marine storage |

Manufacturing & Quality Assurance

For RV Push Locks, buyers need confidence that the product can withstand heavy use and outdoor conditions. This section outlines the manufacturing process and quality checks that ensure consistency and reliability.

Manufacturing Process

Our locks are engineered for a straightforward, drop-in installation. Follow this simple 3-step guide to confirm compatibility and see how easy the process is.

Material Selection

High-strength hardened steel or alloy steel is sourced from certified suppliers. Each batch is tested for tensile strength and corrosion resistance before production.

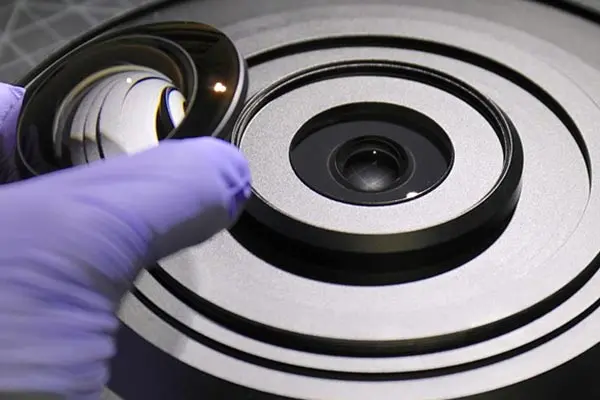

Precision Machining

CNC machining ensures accurate dimensions of lock pins, shank diameters, and coupler interfaces. This minimizes tolerance errors and guarantees smooth operation across different hitch sizes.

Surface Treatment

Anti-corrosion coatings (zinc plating, black powder coating, or stainless finishing) are applied to protect against rust and harsh weather exposure.

Assembly & Lock Cylinder Integration

Each unit is fitted with keyed or push-to-lock cylinders, assembled in dust-controlled environments to prevent contamination.

Quality Assurance

Cycle Testing

Each lock model is tested for over 5,000 locking/unlocking cycles to verify long-term durability.Salt Spray Test

Surface coatings are tested for 72–96 hours in a salt spray chamber, simulating prolonged outdoor exposure.Keyway Reliability

Lock cylinders undergo repeated key insertion and torque tests to ensure consistent operation.Dimensional Checks

100% inspection for pin diameter and coupler fitment tolerance to ensure compatibility with standard 1-7/8”, 2”, and 2-5/16” trailer couplers.

Chat with us now for your custom needs. Contact Our Engineering Team

Where Are RV Push Lock Used?

Application Scenarios

The RV Push Lock is commonly used in furniture and storage applications inside RVs, caravans, and marine vehicles. Below are key scenarios where push locks ensure both convenience and safety.

RV Cabinets

- Prevents accidental opening during driving

- Simple push-to-lock and release operation

- Matches various cabinet designs with multiple finishes

Drawers & Storage Units

- Keeps items secure under road vibration

- Compact design saves space in narrow drawers

- Easy to install and replace without special tools

Wardrobe & Closet Doors

- Ensures wardrobe doors stay closed on bumpy roads

- Smooth push mechanism for daily use

- Available in finishes that blend with interior décor

Caravan & Marine Furniture

- Withstands vibration and moisture in mobile environments

- Provides reliable locking for foldable tables and storage compartments

- Lightweight design without compromising strength

Chat with us now for your custom needs. Contact Our Engineering Team

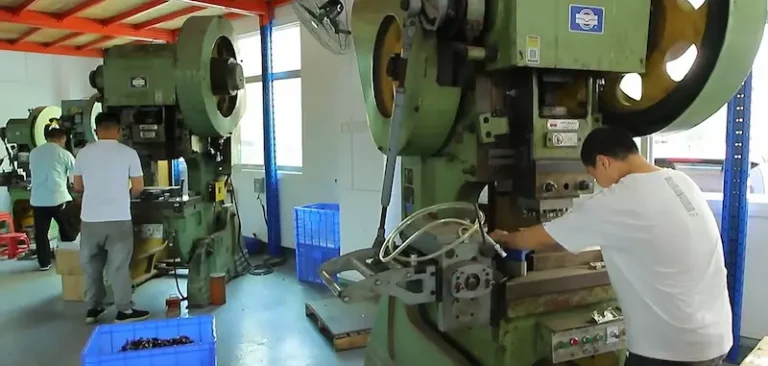

Inside RVlocktech: Factory & Workshop Capabilities

For over 13 years, RVlocktech (DongGuan JUFU Locks Factory Co., Ltd.) has specialized in the design, manufacturing, and supply of RV door locks. Our factory spans 4,000 m² and operates with 6 automatic assembly lines, ensuring consistent output, shorter lead times, and competitive costs for global OEM and wholesale partners.

Factory & Production Capacity

Integrated Manufacturing: Die-casting, injection molding, stamping, machining, and automated assembly all under one roof.

Annual Development: 30+ new lock models designed and tooled in-house every year.

Capacity: Flexible to support both small pilot runs and large-scale OEM programs.

R&D and Customization

In-house R&D team supports concept-to-prototype-to-production.

OEM Services: Custom branding, finishes, keyed-alike systems.

ODM Services: Full design-to-market solutions for new RV lock concepts.

Products comply with international RV standards in US, EU, AU markets.

Our Advantage

Unlike suppliers who rely heavily on outsourcing, RVlocktech controls the entire production process in-house, ensuring:

Consistent quality across orders

Shorter lead times for OEM projects

Cost competitiveness through integrated processes

Your Project Timeline & Key Cost Drivers

We believe in a transparent partnership. Understanding the project lifecycle and the factors that influence cost is crucial for a successful OEM/ODM collaboration. This section provides a clear overview of our typical project timeline and the key engineering decisions that drive the final unit cost.

A Sample OEM Project Timeline

This timeline represents a typical custom lock project, from initial concept to mass production. We maintain a 98% on-time delivery rate for all project milestones.

Step 1: Consultation & Quoting

Submit your specs or drawings; receive a detailed quote and DFM (Design for Manufacturability) feedback from our engineering team within 24 business hours.

Step 2: Prototyping & Approval

We create and deliver functional, pre-production samples for your validation. This stage is typically completed within 2-5 business days.

Step 3: Mass Production

Upon sample approval, your order is scheduled on our ISO 9001 certified production lines, with a standard manufacturing lead time of 10-30 days.

Step 4: Delivery & Support

We manage global logistics to ensure on-time delivery and provide a dedicated account manager for long-term partnership support.

Key Cost Drivers

We provide a fully transparent quote. Understanding these key drivers will help your team make the most cost-effective decisions for your project.

Material & Complexity

The choice between #3 Zinc Alloy and other materials, along with the number of electronic components in a keyless system, are the primary drivers of unit cost. We provide a full cost-benefit analysis.

Order Volume

We offer a tiered pricing structure. Higher annual volumes unlock significant per-unit cost reductions through more efficient raw material procurement and production planning.

Customization Level

Standard modifications, like adding your logo to an existing design, are highly cost-effective. Projects requiring new, unique tooling will have an initial NRE (Non-Recurring Engineering) cost.

Trusted by Industry Leaders & Partners

Increase Values

Hear from them

We don’t just build locks; we build long-term partnerships. Our success is measured by the success of our clients, from leading RV manufacturers to large-scale fleet operators.

How Push Lock Compare to Other RV Lock Types

Push Lock

(Compression Latches vs. Other Lock Types)

RV paddle locks are one of several lock types used in RVs, trailers, and utility vehicles. Choosing between paddle locks, cam locks, compression latches, and handle locks depends on the application, cutout design, and security requirements. Below is a side-by-side comparison for quick evaluation.

| Lock Type | Typical Use Case | Strengths | Limitations |

|---|---|---|---|

| Paddle Lock | RV entry doors, storage compartments, toolboxes | Flush fit design, easy operation, durable, weather-resistant | Slightly larger cutout required compared to cam locks |

| Cam Lock | Cabinets, mailboxes, light-duty panels | Compact size, low cost, easy to install | Limited strength, not ideal for high-security areas |

| Compression Latch | Utility panels, electrical/gas compartments | Tight sealing, vibration resistance, weatherproof | Higher cost, specific installation requirements |

| Handle Lock | RV baggage doors, larger hatches | Easy grip, convenient for frequent access | Bulkier design, may not fit flush applications |

| Hitch Lock | Trailers, towing security | Strong anti-theft protection for trailers | Dedicated use only, not suitable for doors or compartments |

FAQs About RV Push Lock

We Are Here To Help You With Any Questions You May Have

What is an RV Push Lock used for?

RV Push Locks are designed for cabinets, drawers, and furniture inside RVs and caravans to keep them securely closed during travel.

Are push locks vibration-resistant?

Yes. They are engineered to stay locked even when the RV is moving on bumpy roads, reducing the risk of items falling out.

Can RV Push Locks be used in marine or caravan furniture?

Yes, they are suitable for caravans and marine environments where vibration and movement are common.

Do RV Push Locks come in different finishes?

Yes. They are available in finishes such as chrome, matte, and color coatings to match RV interior designs.

How are push locks installed?

They are installed with standard screws and do not require special tools. Most models fit standard cabinet thicknesses.

Can push locks be retrofitted into existing furniture?

Yes, they can replace standard cabinet knobs or handles with minimal adjustment.

Are they child-safe?

Push locks are not child-proof, but they provide resistance that helps prevent accidental opening by children.

What sizes are available?

They are typically available in sizes compatible with common cabinet and drawer thicknesses (e.g., 15–20mm).

What is the minimum order quantity (MOQ) for wholesale?

The MOQ depends on the model, but generally starts from a few hundred units per specification.

Partner with Rvlocktech Today

Submit your technical requirements, CAD files, or project scope. Our engineering team is ready to provide a detailed quote and DFM (Design for Manufacturability) analysis within 24 business hours.

✓ Dedicated Engineering Support

Direct access to our engineering team for all technical inquiries.

✓ Transparent Quoting

A detailed quote that breaks down unit costs, tooling, and materials.

✓ Rapid Prototyping

Functional, pre-production samples delivered in as fast as 10-15 business days.