Precision-Made RV Locks from Certified Manufacturer.

Paddle Metal Lock Electrical Whale Tail Chrome T Handle Remote Control Electric 12 Whale Tail Latch with Car Tool Box Locks

Products Specification

Item No:P606WO-BK

Material:Zinc Alloy

Cut Out:86*25mm

Color:P606WO-BK Black

Panel Thickness:1-6mm

Key combinations:Key Alike/Different key combinations

Application: RV /Caravan /trailer /UTE toolbox/Cannopies etc

Built with high-strength metal and corrosion-resistant finish, our RV locks ensure long-lasting performance in outdoor conditions.

Every lock features precision internal mechanisms and multi-point locking options to provide dependable protection for RV doors and compartments.

Designed for quick replacement and universal fit, each model includes mounting hardware and detailed installation guides for fast setup.

We offer custom logo, finish, and keying systems to match your brand requirements—ideal for OEM and wholesale customers.

Sourcing RV locks for wholesale or OEM projects can be complex. Buyers often need consistent quality, competitive pricing, reliable delivery, and technical support—all without unnecessary risks. At RVLockTech, we provide end-to-end RV lock solutions that simplify the procurement process. From design and mold-making to large-scale production and export logistics, our team ensures every order meets international standards and your business requirements.

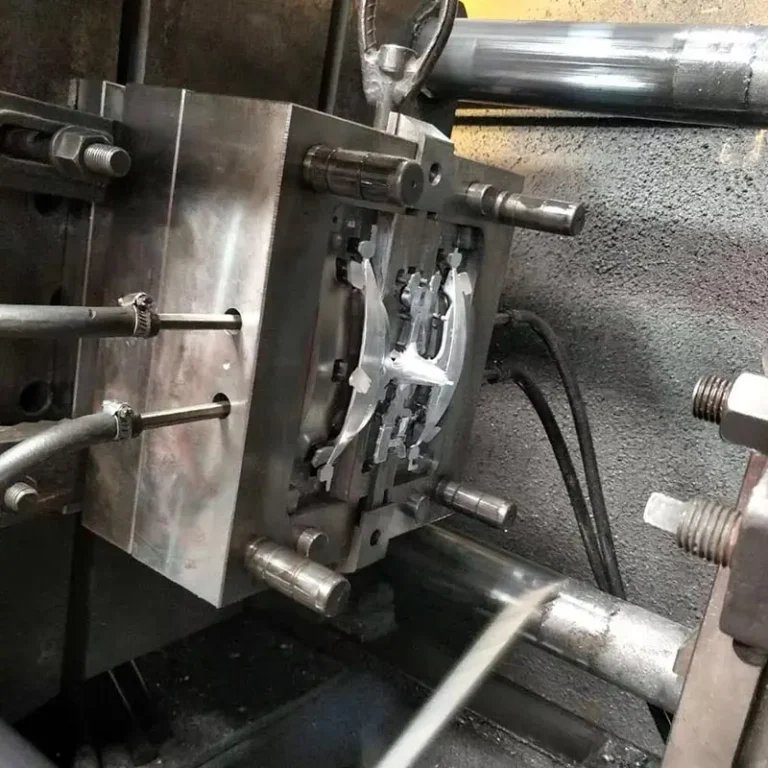

From die-casting, injection molding, stamping, machining to final assembly, every step is controlled under one roof—ensuring consistent quality and reduced risk of delays.

With the ability to produce over 600,000 locks and 300,000 window hardware components monthly, we provide the volume stability that wholesalers and OEM customers require.

Every lock goes through anti-shaking, torque, salt spray, waterproof, and UV testing to ensure durability across different environments—whether for RVs, boats, or industrial use.

Need a unique design for your market? Our in-house design and mold-making team helps turn concepts into real products, supporting private labels and exclusive product lines.

Our workshop covers 4,000 square meters and operates 6 automated assembly lines. We have 180 skilled employees and advanced in-house facilities for:

This allows us to achieve stable monthly output of:

🔒 600,000+ locks for furniture, RVs, and caravans

🪟 300,000+ window hardware components

We control the entire process from raw material to final assembly, ensuring consistent quality, shorter lead times, and competitive pricing for bulk orders.

In-house engineering team assists with lock design, drawings, and technical feasibility to ensure compatibility with RV and industrial applications.

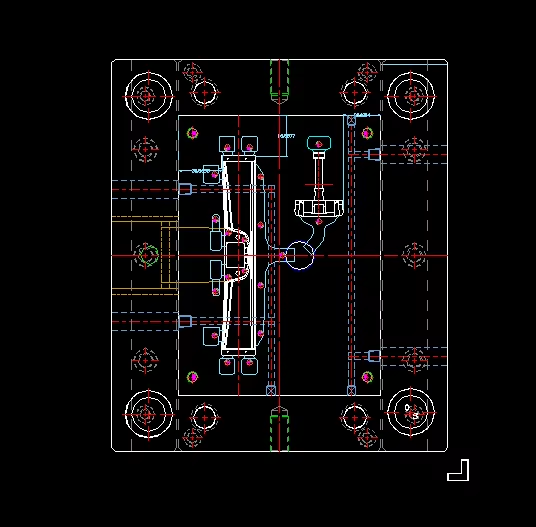

Independent mould workshop for die-casting and injection molds, allowing faster turnaround and lower tooling modification costs.

End-to-end processes including die-casting, stamping, machining, injection molding and surface finishing under one roof.

Complete assembly lines with quality checkpoints, providing ready-to-ship locks and hardware tailored to customer specifications.

Challenge: A European brand required high-volume RV push locks with strict salt spray resistance for coastal markets.

Solution: We customized materials and applied UV & corrosion-resistant coatings, delivering 50,000 units/month with a 98% on-time delivery rate.

Result: Client reduced warranty claims by 30% and expanded into two new markets.

Challenge: Distributor sourcing from multiple suppliers faced inconsistent quality and irregular lead times.

Solution: We consolidated supply by offering a full lock portfolio (door locks, push locks, compression latches, and window hardware) under one order.

Result: Reduced procurement complexity, cut logistics costs by 20%, and improved warehouse efficiency.

Challenge: The manufacturer needed marine-grade compression latches that could withstand both humidity and vibration in long-distance travel.

Solution: We developed a reinforced zinc alloy die-cast version, validated through pull & torque testing in our lab.

Result: Client secured a 3-year supply contract, lowering replacement costs and strengthening product reputation.

We know that sourcing the right RV locks, marine locks, caravan locks, and hardware accessories can be complex. Our solution is built to make it simple and predictable.

Clear insights and a trusted partner for every sourcing step

Our production capacity and operational scale ensure we can deliver RV locks and related hardware on time, with consistent quality.

🔑 600,000+ locks/month – including RV locks, furniture locks, and cabinet locks

🪟 300,000+ window components/month – friction stays and other hardware

🏭 6 automatic assembly lines – stable and efficient production

👩🔧 180 skilled staff – experienced in die-casting, injection, stamping, and assembly

📈 13+ years of experience – specializing in RV locks and industrial hardware

✅ <0.5% annual defect rate – achieved through strict QC and in-house testing

🔄 Cycle Test: 50,000–100,000 opening/closing cycles

🌊 Salt Spray Test: 72–240 hours for corrosion resistance

🔧 Torque Test: 2.5–5.0 Nm to verify strength and stability

💧 Waterproof: Rated IPX4–IPX6 depending on model

☀️ UV Resistance: >500h accelerated exposure testing

🛠 QC Process: Raw material → Die-casting → Machining → Assembly → 100% inspection

The Challenge: Main entry doors on RVs can be opened and closed over 20,000 times in their lifetime, often in extreme temperatures and weather.

What We Do: We engineer both mechanical and keyless locks that undergo 50,000-cycle endurance tests, with reinforced deadbolts and weatherproof seals to handle heat, frost, and UV exposure.

🛡 Weatherproof

🔒 50,000+ Cycles

🌡 -40°C to +80°C

Reduced lock replacement rates for our OEM clients by 35% over 3 years.

The Challenge: Lightweight trailers experience constant vibration and road shock, causing premature wear on standard locks.

What We Do: Our travel trailer locks use solid zinc alloy latches, anti-rattle mechanisms, and corrosion-resistant coatings tested to 240 hours of salt spray.

⚙ Anti-Rattle Design

🧪 240h Salt Spray

🛠 Zinc Alloy Build

Popular with distributors supplying the Midwest and coastal markets due to low warranty returns.

The Challenge: Service trucks and utility trailers carry expensive tools, often parked in unsecured areas. Lost keys or weak locks can mean serious downtime.

What We Do: We produce heavy-duty steel locks with keyed-alike options, allowing operators to secure all compartments with a single master key system.

🔑 Keyed-Alike System

🏗 Heavy-Duty Steel

⏱ Save 200+ Hours

Saved a logistics fleet over 200 labor hours per month in key management.

The Challenge: Saltwater corrosion can destroy standard locks in months, compromising both safety and appearance.

What We Do: Our marine-grade cam locks use stainless steel 316 and anodized aluminum, pressure-tested to resist corrosion in 1,000-hour salt fog tests.

🌊 Marine Grade SS316

🧪 1000h Salt Fog

🚤 Coastal Ready

Adopted by multiple boat trailer OEMs for coastal and offshore applications.

The Challenge: Managing hundreds of vehicles means hundreds of keys — a logistical and security headache.

What We Do: We design keyed-alike and master-key systems that cut the number of keys in circulation by up to 90%.

🗝 Master Key System

⏱ 40% Faster Turnaround

📦 Bulk Supply

A major RV rental company reported a 40% faster turnaround on vehicle preparation.

Looking to add Keyless RV Locks to your product line?

Request OEM pricing, distributor terms, and technical documentation today.

Submit your technical requirements. Our engineering team is ready to provide a detailed quote and a DFM analysis for your project.

+86 15899626300

info@rvlocktech.com