About RVLockTech

RV & Caravan Lock Manufacturer

Discover RVLockTech, a trusted RV & Caravan Lock manufacturer since 2013. OEM/ODM services, strict QC, and reliable supply for global wholesalers & buyers.

Who We Are

RVLockTech (Dongguan JuFu Locks Factory Co., Ltd.) was established in 2013 in Dongguan, Guangdong Province, China. We specialize in the design and manufacturing of RV locks, push locks, cam locks, compression latches, marine locks, panel locks, handle locks, and related industrial locking systems.

With more than a decade of experience, our factory has grown into a reliable B2B partner for wholesalers, distributors, and OEM brands in the RV, caravan, marine, and furniture industries.

Our Manufacturing Capabilities

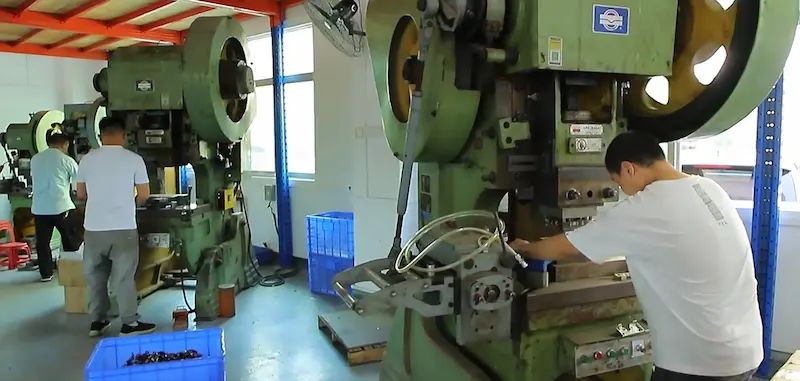

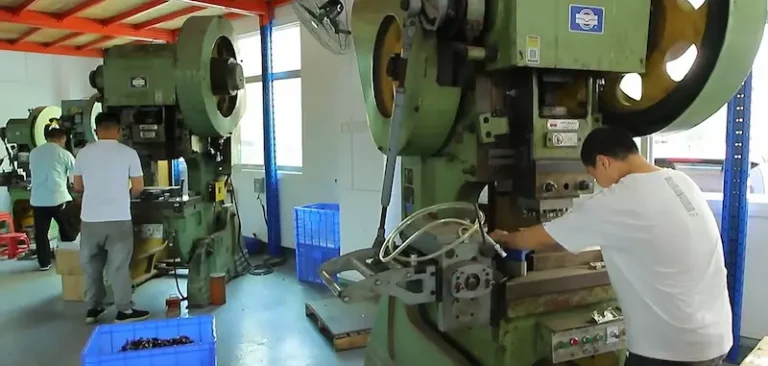

Our workshop covers 4,000 square meters and operates 6 automated assembly lines. We have 180 skilled employees and advanced in-house facilities for:

- 🔧 Die-casting, injection molding, stamping, and machining

- 🏭 Complete assembly and finishing lines

- ✔️ Strict quality control and product testing

This allows us to achieve stable monthly output of:

🔒 600,000+ locks for furniture, RVs, and caravans

🪟 300,000+ window hardware components

We control the entire process from raw material to final assembly, ensuring consistent quality, shorter lead times, and competitive pricing for bulk orders.

End-to-End RV Lock Production

From design and mold development to integrated production and assembly, we deliver complete RV lock manufacturing solutions with strict quality control and reliable capacity.

Product Design Support

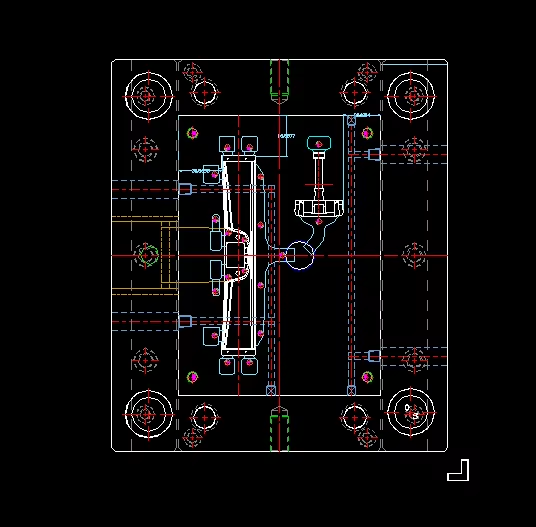

In-house engineering team assists with lock design, drawings, and technical feasibility to ensure compatibility with RV and industrial applications.

Mold Development & Tooling

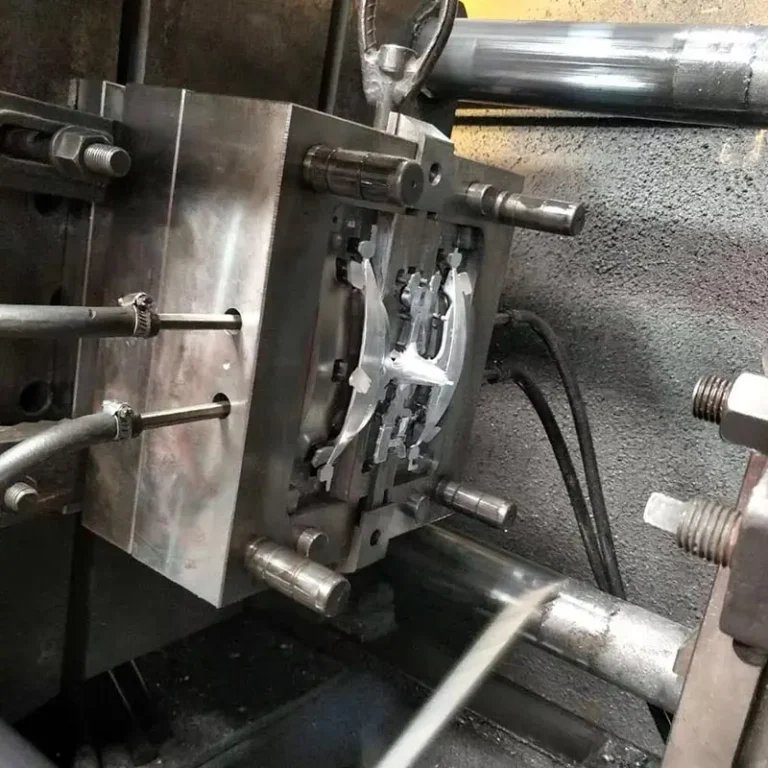

Independent mould workshop for die-casting and injection molds, allowing faster turnaround and lower tooling modification costs.

Integrated Production

End-to-end processes including die-casting, stamping, machining, injection molding and surface finishing under one roof.

Final Assembly & Packaging

Complete assembly lines with quality checkpoints, providing ready-to-ship locks and hardware tailored to customer specifications.

4-Stage Quality Assurance Protocol

Access all the critical engineering data in one place. Compare keyless vs. mechanical locks, check door cutout compatibility, and review material and reliability standards. Designed for engineers and procurement teams to evaluate RV door locks efficiently.

IQC – Incoming Quality Control

Incoming zinc alloy ingots, ABS plastics, and fasteners are inspected against supplier certificates.

IPQC – In-Process Quality Control

Die-casting and machining tolerances checked with ±0.05 mm gauges during production.

FQC – Final Quality Control

Each lock undergoes 100% function testing: deadbolt movement, keypad/remote response, and key override.

OQC – Outgoing Quality Control

AQL 0.65 random sampling, packaging integrity check, and labeling verification before shipment.

Chat with us now for your custom needs. Contact Our Engineering Team

Inside RVlocktech: Factory & Workshop Capabilities

For over 13 years, RVlocktech (DongGuan JUFU Locks Factory Co., Ltd.) has specialized in the design, manufacturing, and supply of RV door locks. Our factory spans 4,000 m² and operates with 6 automatic assembly lines, ensuring consistent output, shorter lead times, and competitive costs for global OEM and wholesale partners.

Factory & Production Capacity

Integrated Manufacturing: Die-casting, injection molding, stamping, machining, and automated assembly all under one roof.

Annual Development: 30+ new lock models designed and tooled in-house every year.

Capacity: Flexible to support both small pilot runs and large-scale OEM programs.

R&D and Customization

In-house R&D team supports concept-to-prototype-to-production.

OEM Services: Custom branding, finishes, keyed-alike systems.

ODM Services: Full design-to-market solutions for new RV lock concepts.

Products comply with international RV standards in US, EU, AU markets.

Our Advantage

Unlike suppliers who rely heavily on outsourcing, RVlocktech controls the entire production process in-house, ensuring:

Consistent quality across orders

Shorter lead times for OEM projects

Cost competitiveness through integrated processes

EXHIBITIONS & EVENTS

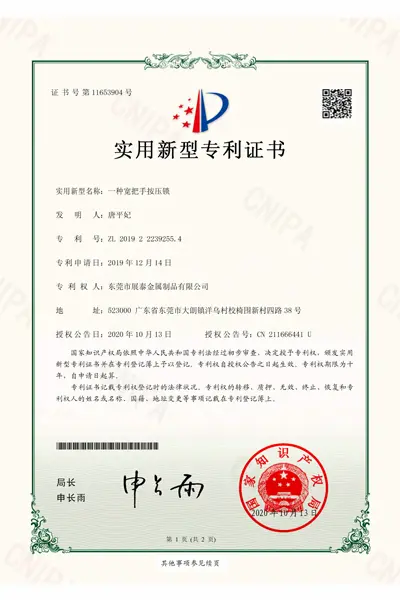

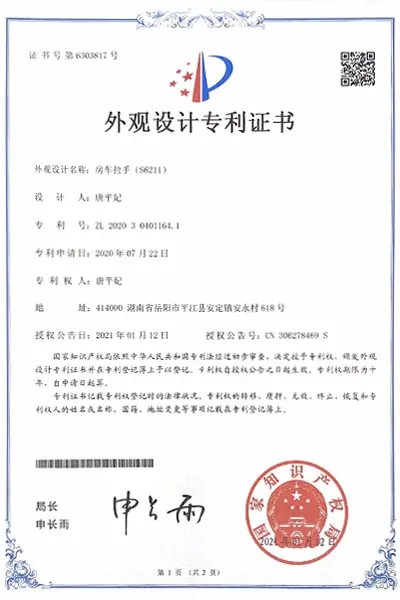

OUR CERTIFICATE

Partner with Rvlocktech Today

Submit your technical requirements, CAD files, or project scope. Our engineering team is ready to provide a detailed quote and DFM (Design for Manufacturability) analysis within 24 business hours.

✓ Dedicated Engineering Support

Direct access to our engineering team for all technical inquiries.

✓ Transparent Quoting

A detailed quote that breaks down unit costs, tooling, and materials.

✓ Rapid Prototyping

Functional, pre-production samples delivered in as fast as 10-15 business days.