RV Door Locks — Keyless & Mechanical Entry Systems

Tested to 100,000+ cycles, 96h salt-spray, and OEM-standard fit for major RV door cutouts.

Securing your RV begins with the right door lock. At Rvlocktech, we specialize in OEM & ODM manufacturing of high-quality RV door locks designed for different vehicle types and applications. With ISO-certified production, advanced testing, and full customization options, we help RV manufacturers, brand owners, and distributors deliver safe, reliable, and market-ready solutions.

Rv Lock Manufacturer

Durable RV door locks designed for OEMs and distributors. Available in both mechanical and keyless models to enhance security and convenience.

Primary Materials

#3 Zinc Alloy, UV-Stabilized ABS, Hardened Steel

ASTM B86-13, RoHS Compliant

Core Processes

High-Pressure Die-Casting, CNC Machining, Stamping

±0.05mm Critical Tolerance

Finishing Options

Powder Coating, Electroplating (Chrome, Nickel)

96-hour Salt Spray Tested

Performance Testing

Cycle Life, Environmental Chamber (-40°C to 80°C), Vibration

Engineering & Design Support

DFM Analysis, 3D Modeling (SolidWorks), Rapid Prototyping

<24hr Technical Inquiry Response

Certification Standards

ISO 9001:2015 ISO 14001

Audited Annually

RV Keyless Entry Door Locks

Keyless entry systems are increasingly popular among RV users who prefer convenience and added security. Our keyless locks are compatible with most RV models, featuring stable electronic components and weather-resistant construction.

- 🔑 PIN & Key Access – Multiple unlocking options for flexibility.

- ⚡ Battery Efficient – Low-power consumption with warning alerts.

- 🌧 Weather Resistant – Designed for outdoor use, resistant to dust and moisture.

RV Mechanical Door Locks

Mechanical RV door locks remain a reliable choice for fleets, rental RVs, and budget-conscious buyers. Built with zinc alloy or stainless-steel cores, they provide long service life with simple key-based access.

- 🔒 Proven Reliability – Traditional locking system with stable performance.

- 🛠 Easy Replacement – Standard sizes for quick installation and interchangeability.

- 🪙 Cost-Effective – Practical solution without compromising security.

Technical Specifications & Fitment Center

Access all the critical engineering data in one place. Compare keyless vs. mechanical locks, check door cutout compatibility, and review material and reliability standards. Designed for engineers and procurement teams to evaluate RV door locks efficiently.

Fitment & Cutout Guide

Check standard RV door thicknesses (25–45 mm) and cutout sizes (2-3/4″, 3-1/2″, etc.) matched to compatible lock models.

| Door Thickness (mm) | Cutout Size (mm) | Compatible Models | Notes |

|---|---|---|---|

| 25–35 | 68 × 92 | Paddle Handle, Deadbolt | Most trailers/campers |

| 35–45 | 70 × 100 | Keyless Keypad, Remote Fob | Motorhome fitment |

| 20–28 | 65 × 85 | Compact Lever Locks | Campervan & retrofits |

Keyless vs Mechanical Locks

Side-by-side technical comparison of power source, ingress protection, failure modes, user management, and lifecycle cost. Helps you decide which lock type fits your RV model and end-user needs.

| Feature | Keyless Entry | Mechanical Locks |

|---|---|---|

| Power Requirement | Battery (CR123A/AA) | None |

| Ingress Rating | IP65 (sealed electronics) | Weather-sealed mechanism |

| Backup Access | Mechanical override key | N/A |

| Cycle Life | 80,000–100,000 cycles | 100,000+ cycles |

| Cost Impact | Higher initial cost | Lower initial cost |

Materials & Surface Treatments

Detailed breakdown of housing alloys, coatings, seals, and test results: 100,000+ cycle life, 96-hour salt-spray, and IP65 ingress protection. Includes RoHS/REACH compliance and QC checklist for audit readiness.

| Component | Material | Finish Options | Test Result |

|---|---|---|---|

| Housing | Zinc Alloy #3 | Black powder coat | 96h+ ASTM B117 |

| Handle | UV-stabilized ABS | Textured / smooth | UV-tested |

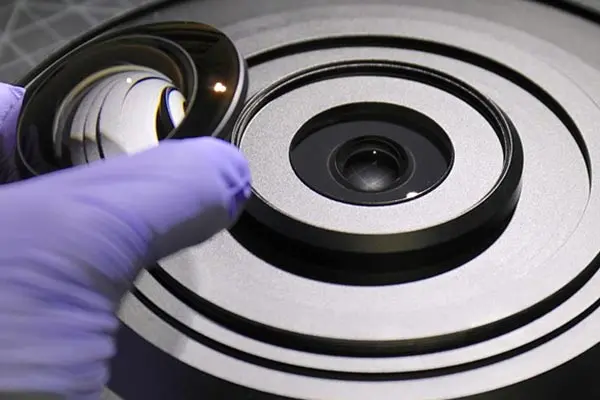

| Cylinder | Brass / zinc core | Chrome / nickel | 100,000+ cycles |

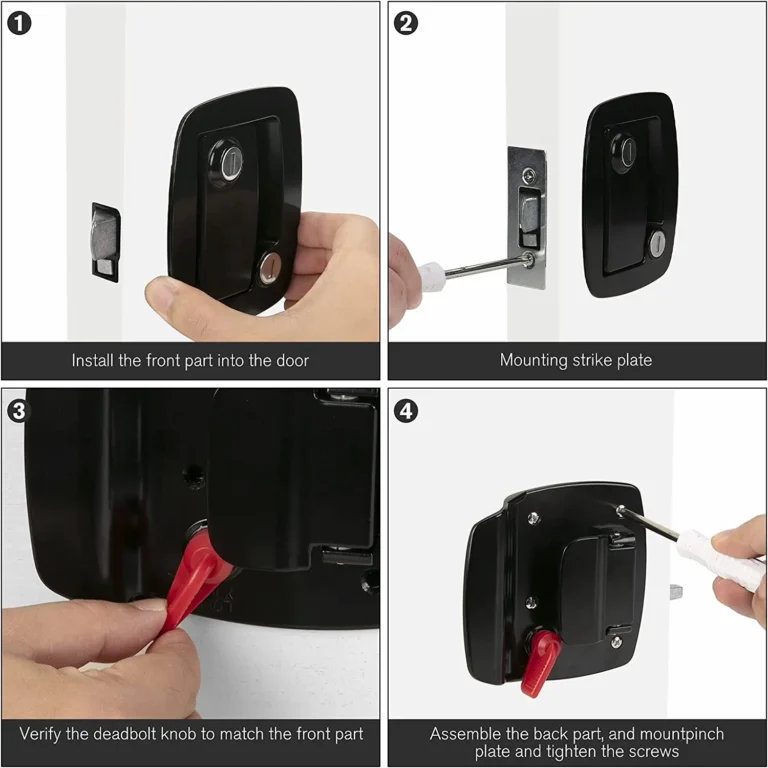

Easy Installation & Replacement

Our RV door locks are designed for direct replacement. Standardized cutouts ensure compatibility with most RV models, reducing downtime for repair shops and fleet operators.

3-Step Installation & Fitment Guide

Our locks are engineered for a straightforward, drop-in installation. Follow this simple 3-step guide to confirm compatibility and see how easy the process is.

Step 1: Confirm Your Cutout Size

he vast majority of our locks are designed to fit the industry-standard. Use a tape measure to check your existing opening. If it matches these dimensions, our lock will be a direct fit.

Step 2: Measure Your Door Thickness

Our locks are compatible with a standard door thickness. Simply measure the edge of your door to ensure it falls within this range. This guarantees the interior and exterior handles will fit together perfectly.

Step 3: The 10-Minute Installation Process

1. Remove the old lock: Unscrew the handful of screws holding your existing lock in place.

2. Install the new lock: Slide the new Rvlock into the opening and secure it with the provided screws.

3. Power up (for keyless models): Insert the batteries, and your new lock is ready to program and use.

Chat with us now for your custom needs. Contact Our Engineering Team

4-Stage Quality Assurance Protocol

Access all the critical engineering data in one place. Compare keyless vs. mechanical locks, check door cutout compatibility, and review material and reliability standards. Designed for engineers and procurement teams to evaluate RV door locks efficiently.

IQC – Incoming Quality Control

Incoming zinc alloy ingots, ABS plastics, and fasteners are inspected against supplier certificates.

IPQC – In-Process Quality Control

Die-casting and machining tolerances checked with ±0.05 mm gauges during production.

FQC – Final Quality Control

Each lock undergoes 100% function testing: deadbolt movement, keypad/remote response, and key override.

OQC – Outgoing Quality Control

AQL 0.65 random sampling, packaging integrity check, and labeling verification before shipment.

Chat with us now for your custom needs. Contact Our Engineering Team

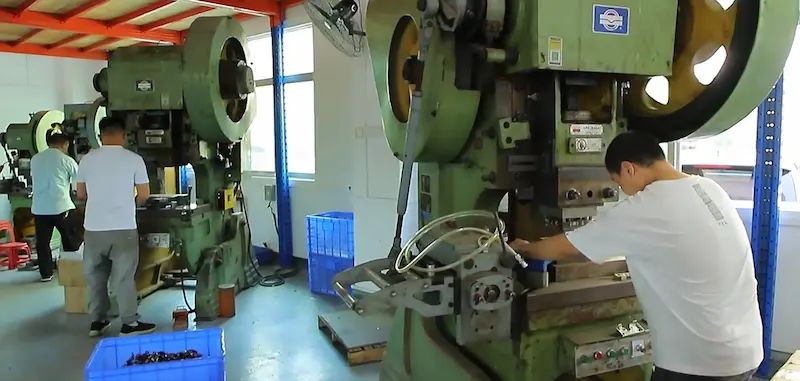

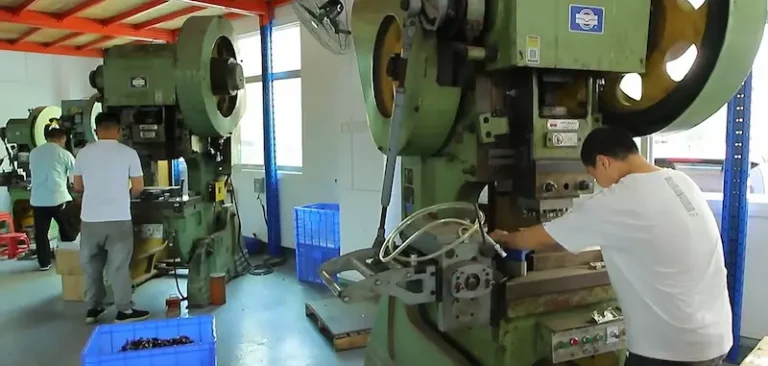

Inside RVlocktech: Factory & Workshop Capabilities

For over 13 years, RVlocktech (DongGuan JUFU Locks Factory Co., Ltd.) has specialized in the design, manufacturing, and supply of RV door locks. Our factory spans 4,000 m² and operates with 6 automatic assembly lines, ensuring consistent output, shorter lead times, and competitive costs for global OEM and wholesale partners.

Factory & Production Capacity

Integrated Manufacturing: Die-casting, injection molding, stamping, machining, and automated assembly all under one roof.

Annual Development: 30+ new lock models designed and tooled in-house every year.

Capacity: Flexible to support both small pilot runs and large-scale OEM programs.

R&D and Customization

In-house R&D team supports concept-to-prototype-to-production.

OEM Services: Custom branding, finishes, keyed-alike systems.

ODM Services: Full design-to-market solutions for new RV lock concepts.

Products comply with international RV standards in US, EU, AU markets.

Our Advantage

Unlike suppliers who rely heavily on outsourcing, RVlocktech controls the entire production process in-house, ensuring:

Consistent quality across orders

Shorter lead times for OEM projects

Cost competitiveness through integrated processes

Your Project Timeline & Key Cost Drivers

We believe in a transparent partnership. Understanding the project lifecycle and the factors that influence cost is crucial for a successful OEM/ODM collaboration. This section provides a clear overview of our typical project timeline and the key engineering decisions that drive the final unit cost.

A Sample OEM Project Timeline

This timeline represents a typical custom lock project, from initial concept to mass production. We maintain a 98% on-time delivery rate for all project milestones.

Step 1: Consultation & Quoting

Submit your specs or drawings; receive a detailed quote and DFM (Design for Manufacturability) feedback from our engineering team within 24 business hours.

Step 2: Prototyping & Approval

We create and deliver functional, pre-production samples for your validation. This stage is typically completed within 2-5 business days.

Step 3: Mass Production

Upon sample approval, your order is scheduled on our ISO 9001 certified production lines, with a standard manufacturing lead time of 10-30 days.

Step 4: Delivery & Support

We manage global logistics to ensure on-time delivery and provide a dedicated account manager for long-term partnership support.

Key Cost Drivers

We provide a fully transparent quote. Understanding these key drivers will help your team make the most cost-effective decisions for your project.

Material & Complexity

The choice between #3 Zinc Alloy and other materials, along with the number of electronic components in a keyless system, are the primary drivers of unit cost. We provide a full cost-benefit analysis.

Order Volume

We offer a tiered pricing structure. Higher annual volumes unlock significant per-unit cost reductions through more efficient raw material procurement and production planning.

Customization Level

Standard modifications, like adding your logo to an existing design, are highly cost-effective. Projects requiring new, unique tooling will have an initial NRE (Non-Recurring Engineering) cost.

Trusted by Industry Leaders & Partners

Increase Values

Hear from them

We don’t just build locks; we build long-term partnerships. Our success is measured by the success of our clients, from leading RV manufacturers to large-scale fleet operators.

FAQs About RV Door Locks

We Are Here To Help You With Any Questions You May Have

What production volumes can RVlocktech support?

We handle both small pilot runs (500 units) and mass OEM programs (100,000+ units annually) with the same QA process. This ensures flexibility whether you are testing a new RV model or scaling up production.

Can you customize locks for regional compliance?

Yes. Our engineering team adjusts lock designs for North American, European, and Australian RV standards, including cutout sizes and safety requirements.

What are the typical cutout dimensions for RV door locks?

Most RV door locks fit cutouts of 2.67" × 3.6" (68 × 92mm) with a standard door thickness of 1.25"–1.5" (32–38mm). For OEM projects, we can adapt cutouts to your existing door panel specifications.

How fast can prototypes be delivered?

Prototyping is available in as little as 15 working days, depending on the complexity of tooling. For designs requiring new molds, we integrate mold-making in-house, saving several weeks compared to outsourcing.

Can RV locks be keyed alike across multiple units?

Yes. We provide keyed-alike systems for fleet or OEM builds, meaning one key can operate multiple RVs in a production line or rental fleet.

What are the most common failure points in RV locks?

Industry data shows failures typically occur in springs, latch mechanisms, or low-grade alloys. Our design uses reinforced zinc alloy + steel springs to reduce these risks.

Can electronic locks interfere with RV electrical systems?

No. Bluetooth and keypad locks are low-voltage (≤6V) and isolated from RV main circuits. They operate independently and don’t affect vehicle electronics.

What customization options are available for OEM projects?

Options include logo engraving, custom colors, surface finishes (matte, gloss, chrome), handle shapes, and smart integration (Bluetooth, keypad, fob).

What security standards apply to RV door locks?

While no global RV-specific lock standard exists, we design to meet ANSI/BHMA Grade 2 equivalent performance, which balances security and operational durability.

Partner with Rvlocktech Today

Submit your technical requirements, CAD files, or project scope. Our engineering team is ready to provide a detailed quote and DFM (Design for Manufacturability) analysis within 24 business hours.

✓ Dedicated Engineering Support

Direct access to our engineering team for all technical inquiries.

✓ Transparent Quoting

A detailed quote that breaks down unit costs, tooling, and materials.

✓ Rapid Prototyping

Functional, pre-production samples delivered in as fast as 10-15 business days.